This lightweight super alloy is used heavily in medical and aerospace applications because of its strength, durability and limited mass.

Industries that utilize this material carry heavy liability and need to ensure that the marking being performed is safe and non-damaging.

Aerospace applications require heavy fatigue testing to ensure no structural damage is incurred by the titanium part by way of Heat Affected Zones (HAZ), recasting/remelt layers, or micro-cracking.

Not all lasers are capable of performing such markings.

For the medical industry, most titanium parts are actually placed inside of the human body permanently, or for surgical tools which will be used inside of the human body.

Because of this, markings must be sterile and durable.

Also, these marked parts or tools must be approved by the FDA to ensure that they are truly inert and safe for their intended use.

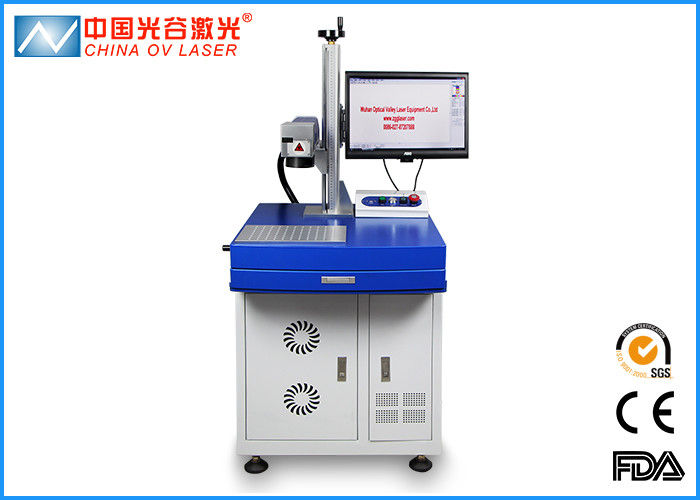

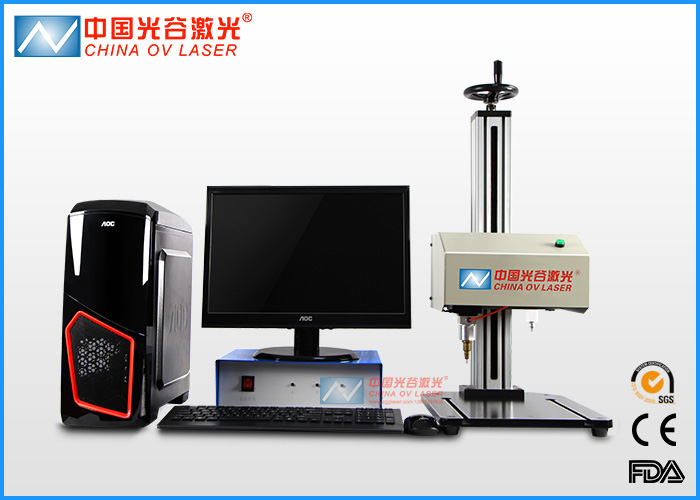

ZGG laser marking machine is capable of marking on titanium and the ideal system for your application depends on your marking requirements.

Titanium lends itself to all marking techniques but the best laser and technique depend on the application.

The aerospace industry uses annealing to limit structural damage.

Medical instruments are annealed, etched or engraved depending on the intended lifecycle and use of the implement.